When an ERP Implementation Gives You Lemons, Make Lemonade

ERP Implementation

Decision makers across the manufacturing space are fed up with botched Enterprise Resource Planning (ERP) Implementations. Majority of manufacturers are stuck with implementations that are over budget and/or behind schedule. After a certain point, companies are prepared to pull the plug on the entire operation. As a leader, what do you do at that point? According to CEO Ruben Mirensky, you call IMCO Software. IMCO has put together an innovative team of consultants who specialize in turning troublesome ERP lemons into fresh lemonade.

THE LEMONS

Statistics show a vast majority of manufacturers are unsatisfied with current ERP implementation projects because:

- 86% of live ERP implementations report not attaining original goals.

- 92% of present ERP implementations report being substantially behind schedule and/or having budget overruns.

- 34% of ERP projects are closed before completion without attaining core functionalities stated at inception.

These numbers represent a huge financial loss in regards to time, labor, and training.

# 1 – Not meeting original goals

The most common scenario manufacturing companies are faced with is not meeting or beating initial goals. This often creates an environment where team members start “finger pointing” trying to find a scapegoat to blame. What causes this to happen? For some, it is caused by not having items completed correctly before beginning the project itself. We are all familiar with the phrase “Dot Your I’s And Cross Your T’s”. This simple idiom contains so much truth in regards to ERP implementations. Why? ERP Implementations require a concrete foundation before starting. If your data isn’t correct, your project goals will be unrealistic and your strategy will fail. Most manufacturer’s waste time by applying a “Band-Aid” type of fix instead of utilizing a sustainable solution like what IMCO Software is offering.

# 2 – Running behind schedule and/or budget overruns

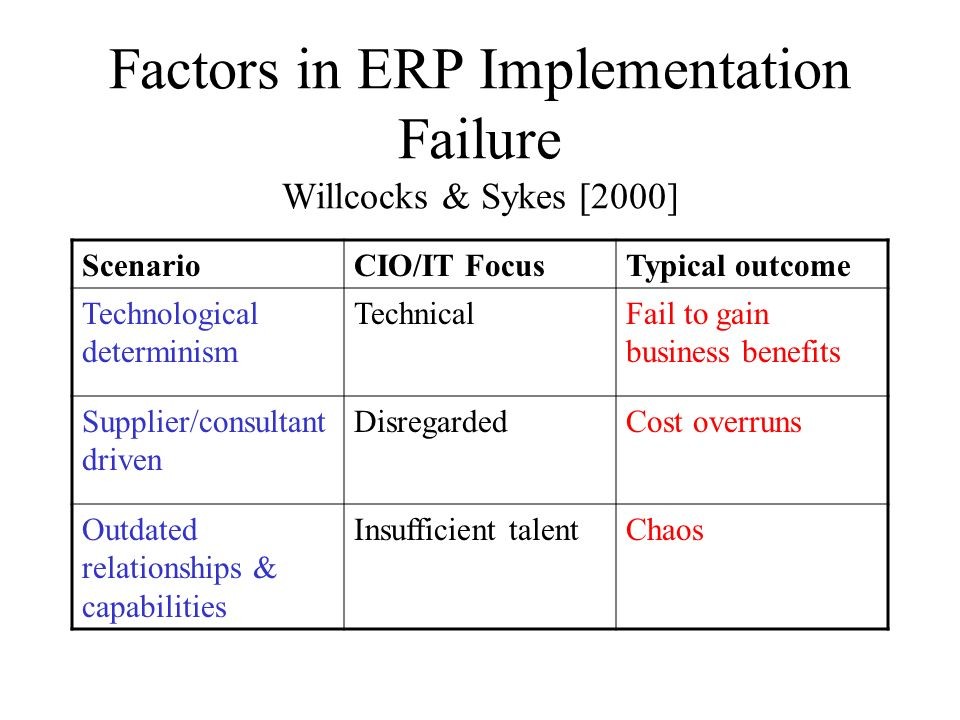

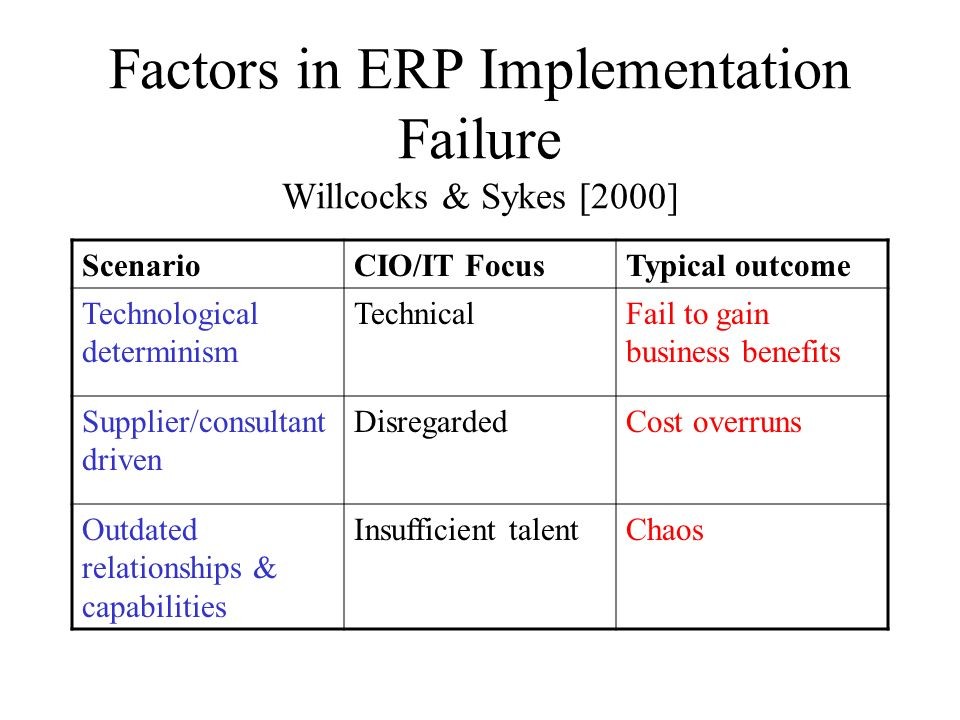

What do you do when your project is way behind schedule and your budget is in the red? This is typically considered the “nail in the coffin” for ERP projects because it’s when most leadership boards give up. Before we discuss what to do from this point, we need to understand why so many manufacturing companies get stuck at this point! Here are three key reasons for ERP Implementation timeline and budget overruns:

- The amount of time needed to invest in training for the software was underestimated

- Limited communication between departments

- The decision on software was determined by the ERP developer’s reputation or great sales pitch

ERP implementations require substantial investments. This may seem like an obvious statement, but statistics show that many projects fail because leadership underestimated the time that was needed to invest in training. Every employee from the supervisors to operators on the floor require training on the new ERP software. This can make or break an entire project timeline.

There is a consistent trend that leads to those three mistakes listed above. Do you know what it is? The future needs of the company were not considered before starting the ERP project. We’ll discuss this idea more in the next point.

# 3 – Closing ERP Projects before completion without attaining any core functionalities

The average timeline for an ERP Implementation is about three to five years. There are four main phases during this time span:

- The Analysis Phase

- The Design Phase

- The Construction Phase

- The Cutover Phase

Proper planning in the analysis phase is key for having a successful ERP Implementation. Many manufacturers are forced to close ERP projects before completion without attaining any core functionalities because something was overlooked during this phase. Once a red flag appears during the design phase, leadership is forced to make a decision on whether to continue working on the project or close it. IMCO Software CEO Ruben Mirensky considers this to be the most troublesome element for businesses dealing with an at-risk implementation. It is extremely difficult to overcome obstacles in these ERP project phases without outside help from knowledgeable consultants.

THE LEMONADE

Before closing ERP operations entirely, Mirensky recommends contacting his team to make the most of what your company has remaining (aka taking lemons and making lemonade). According to the IMCO Software CEO, “The most productive thing to do when ERP implementations get into trouble is to find a solution instead of playing the blame game.” Mirensky’s company provides manufacturers the opportunity to salvage at least some of the time, labor, and training already invested into the ERP implementation project.

So now comes the main question, how does IMCO Software make lemonade? IMCO’s expert team of consultants provides companies an affordable solution when dealing with troubled ERP Implementations. According to IMCO Software’s website, “Our consultants have developed an expertise in bringing projects to their best possible conclusion.” How? They have a strong track record for utilizing the ERP project AS IS. IMCO Software adopts whatever ERP system you chose during the analysis phase. Their innovative team then adapts to the original project design to finalize the cut-over phase at a minimum cost. If your ERP implementation is at-risk, and your company is ready to transform ERP lemons into fresh lemonade, contact IMCO Software today.

Schedule your free ERP consultation by calling 888-558-7887 or contact IMCO online by submitting a contact form here

More From Us

The Importance of Real Time Information in a Manufacturing Environment

The Importance of Real Time Information in a Manufacturing Environment To remain competitive in today’s global manufacturing space, companies need to be able to install...

Read MoreA Guide to Sustainable Manufacturing using EnergyMax Software

A Guide to Sustainable Manufacturing using EnergyMax Software Revenue generation isn’t the only target manufacturers work toward annually. In fact, a variety of key performance...

Read MoreEvolving into Industry 4.0’s Smart Factory with CIMAG MES

Evolving into Industry 4.0’s Smart Factory with CIMAG MES The trend of using digital information to improve efficiency is on the rise across manufacturing companies...

Read MoreThe Opportunity Cost of Working Capital Tied up in Inventory

The Opportunity Cost of Working Capital Tied up in Inventory Measuring a manufacturer’s financial health involves taking into consideration a variety of factors. Many agree...

Read More