Manufacturing Long-Term Planning

Coordinate Demand and Capacity Planning to Improve Customer Service and Production

Implement and maintain an SIOP process successfully.

Equip your operation with the ability to combine multiple data points from various sources to create an unlimited number of planning scenarios for your business.

Explore Features and Benefits

- CONFIGURABLE FORECASTING

- DYNAMIC

- INTEGRATIONS

Multiple Planning Horizons

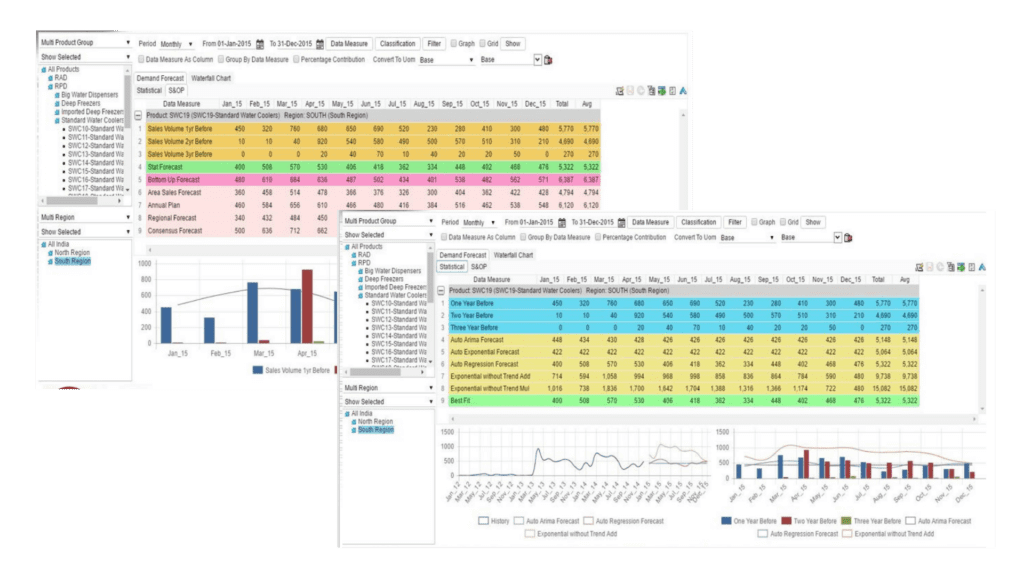

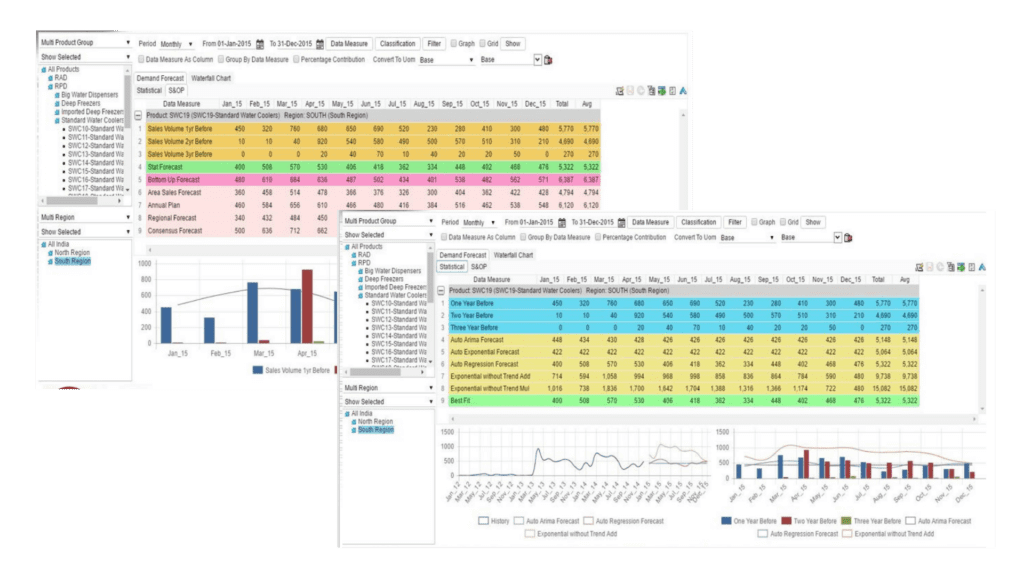

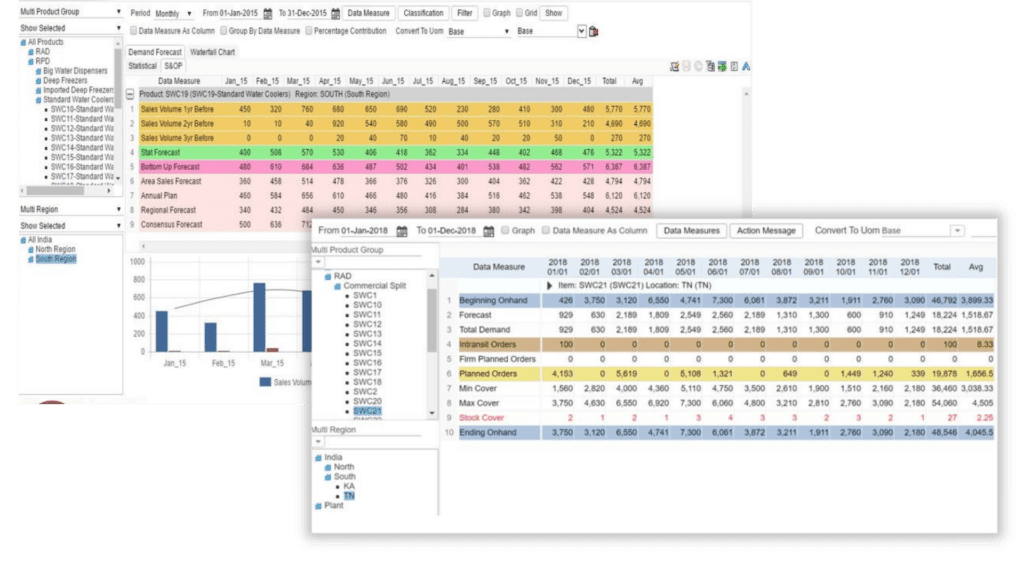

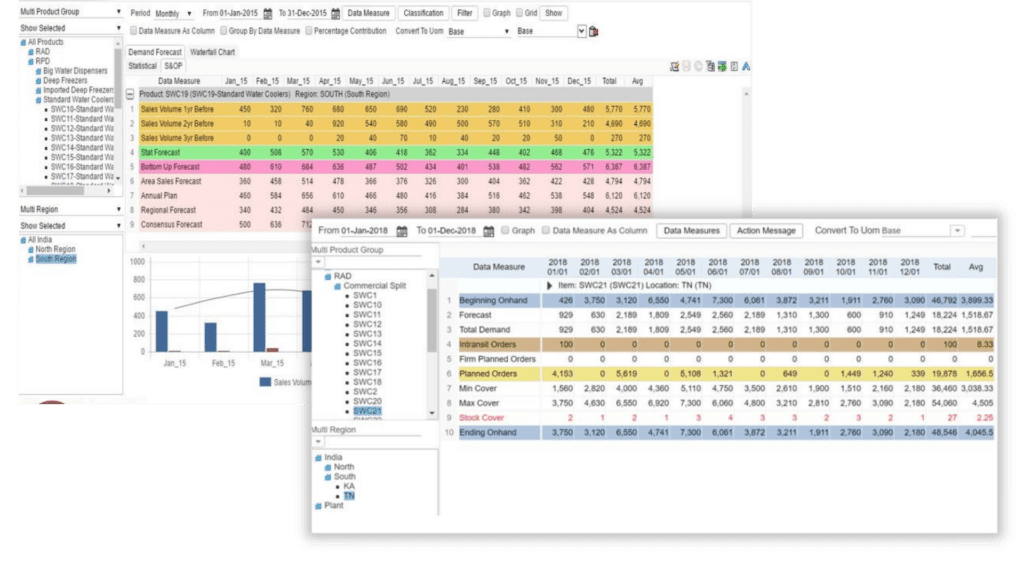

Equip your operation with the ability to combine multiple data points from various sources to create an unlimited number of planning horizons and scenarios for your business. Forecasting abilities for Staff, Inventory, Equipment, Packaging, and Vendors.

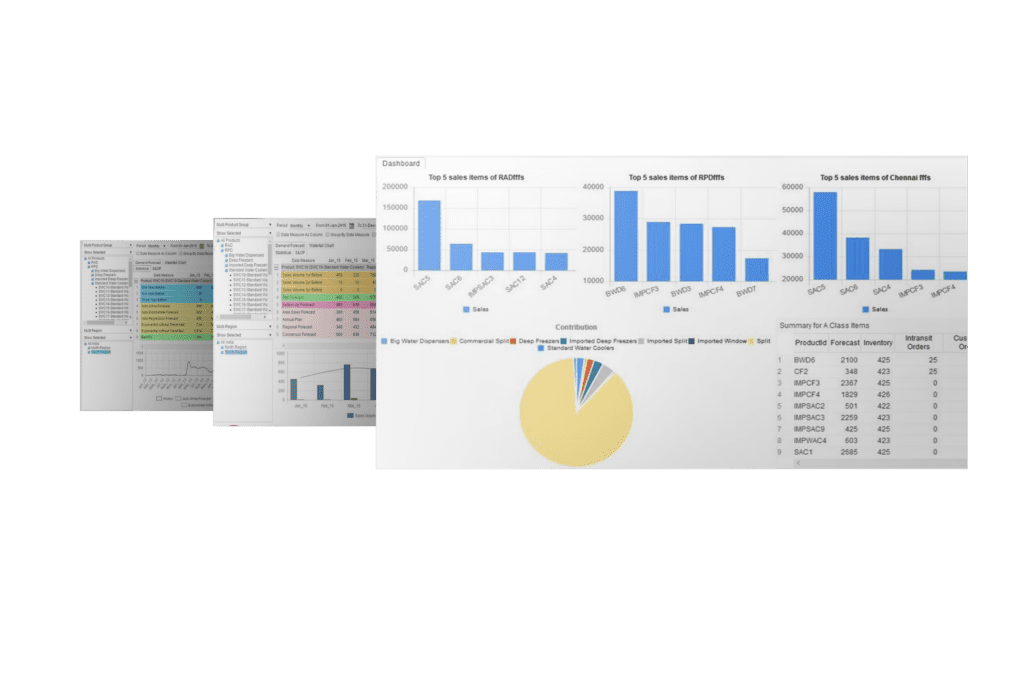

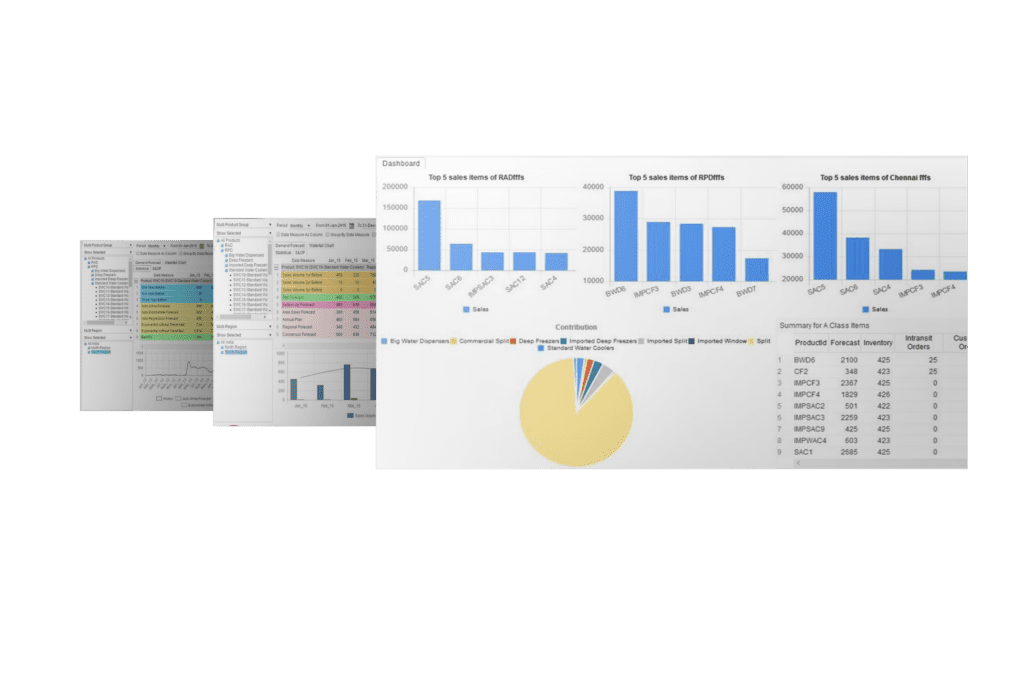

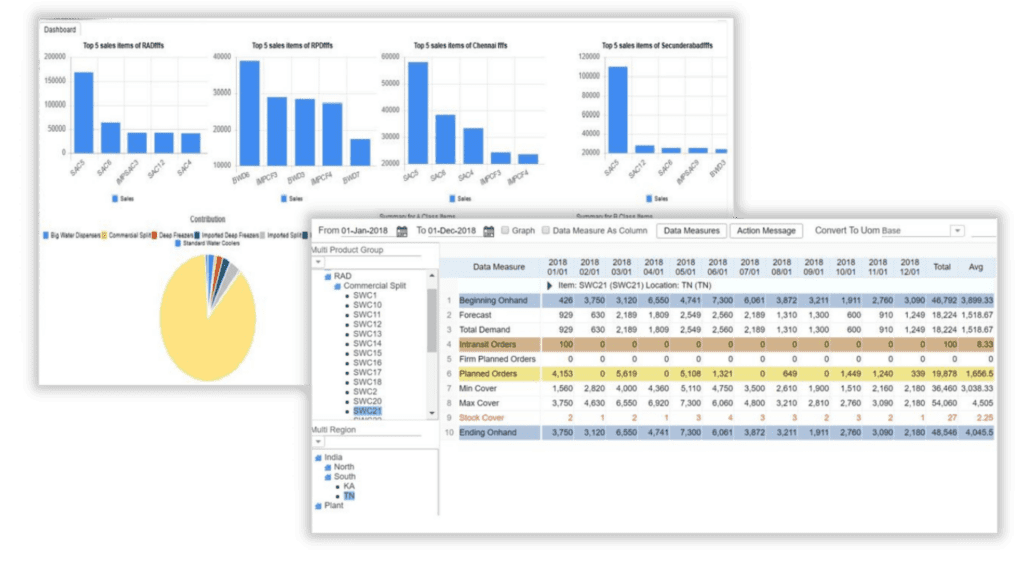

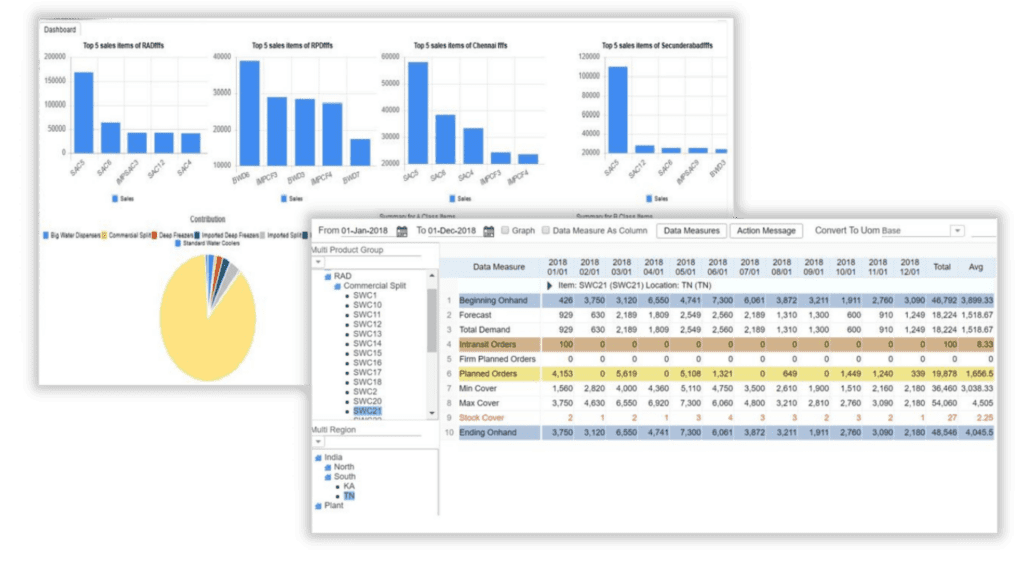

Integrated Analysis

Coordinate demand and capacity planning to improve customer service and production with the capability to create multiple horizon scenario configurations. The application provides a Best Fit model among 20 predicted models.

ERP Compatibility

Fully integrates with your existing ERP system and provides the tools to implement and maintain a SIOP process successfully.

BROCHURES

Plan360: Long Term Planning

Sync demand, long-, mid-, and short-term planning to minimize manufacturing surprises.

Streamline Demand Planning Across All Variables

Complete SIOP Management

Multiple Planning Scenario Configurations

"Best Fit" Demand Model Among 20 Predicted Models

Forecast Staff, Inventory, Equipment, Packaging & Vendors

Improve Lead Time

Reduce New Product Introduction Time

Have a challenge? We have the solution

Maximize uptime with absolute minimum materials.

Real-time upstream and downstream product and process traceability

Respond successfully to changing demand

Support any discrete manufacturing process on-the-fly

Use computer learning to avoid unplanned downtime and increase productivity.

Quality Management for all aspects of the operation.

Latest insights for exceptional quality

Inbound material quality, in-process quality, outbound product quality, and corrective & preventive actions

Improving Manufacturing Lead Time in 2023

Technological innovation is driving a fourth industrial revolution (Industry 4.0) within the...

Read MoreWhat to Expect in the Chemical & Plastics Industries in 2023

Like many industries, the chemicals and plastics manufacturing space has drastically transformed...

Read MoreForward vs. Backward Traceability in Manufacturing

Traceability remains a buzzword in the manufacturing world, and for good reason....

Read MoreLearn how IMCO Software can help you achieve the perfect manufacturing process.

Request a consultation to see how we can help