How to Increase Your ERP's Effectiveness by Implementing an MES

Introduction

In this blog, we will talk about how to implement MES (Manufacturing Execution Systems), and ERP systems. We will also look at long-term planning in a different way than the norm. We will challenge the perception of MES as an extension of ERP systems, and instead look at them as the foundation of successful ERP implementations.

MES is the Foundation of Successful ERP Implementations

MRP and MRPII functionalities, the parts of ERP systems that deal with Materials and Capacity Planning respectively, use a “management by exception” approach to delivering their benefits. Parameters and calculations are there to ensure that customer service is at the optimal level, the least amount of working capital in inventory and fixed assets are being used, and disruptions are avoided so the business can run as normal.

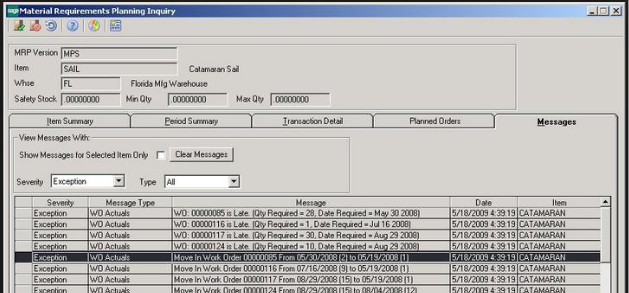

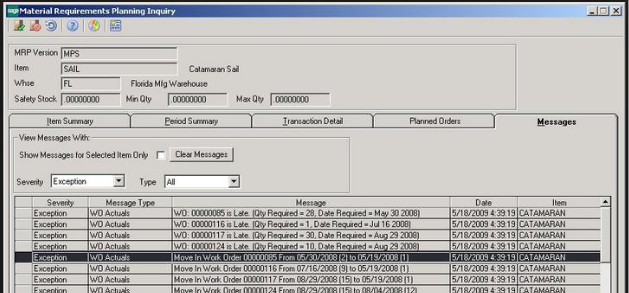

With those parameters and calculations, the system generates a plan. When that plan cannot be achieved without human intervention, an alert message is sent:

- If, to fill a requirement, the time needed to get the item is less than normal, an alert saying “Lead-time Violation” will appear.

- If a requirement is inside the frozen planning horizon – the time period where changes cannot be accepted automatically – the system will put it at the end of the time period and an alert saying “Expedite” will appear.

- If a requirement is postponed, and the requirement is already being satisfied, an alert saying “De Expedite” will appear.

- If a requirement is cancelled, and the requirement is already being satisfied, an alert saying “Cancel” will appear.

For the system to succeed regarding our desired outcome, the following need to take place:

- Messages need to be real. Flooding the system with incorrect messages defeats our goal of planning and scheduling management.

- Messages need to be clear. They should not require research to figure out what they mean.

- Messages need to be correct. The message should not make you do something that is different than what actually needs to be done.

For messages to conform to those requirements, data must be:

- Data inaccuracy (wrong materials, wrong quantity reported, etc.) will create incorrect messages that require you to review them, which creates more work (which is the opposite of our goal).

2. Data updates need to be in near-real time, making sure that actions and decisions made are as close to correct as possible. Untimely data updates could create messages that contradict with a later message, creating the same issues as inaccurate data.

When and Why Did Data Acquisition Lag Behind MRP and MRPII Logic

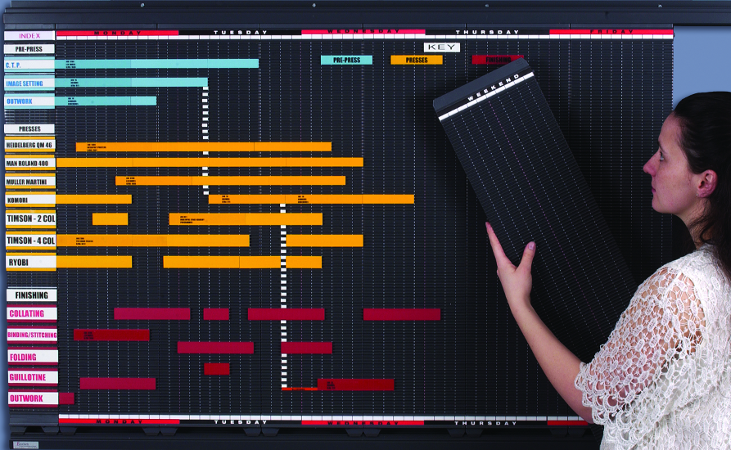

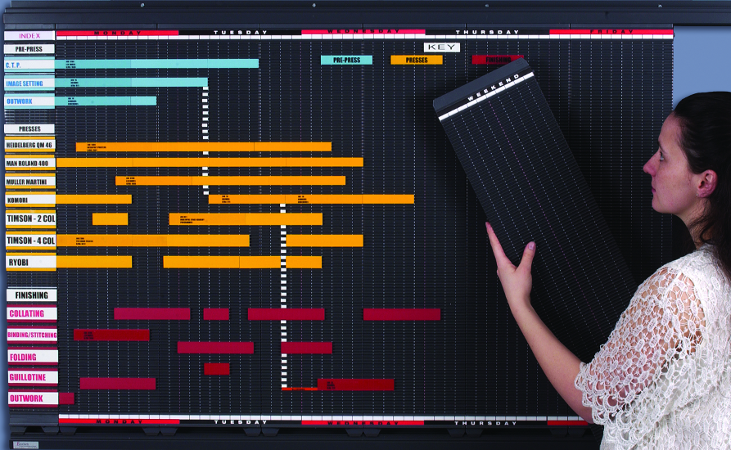

25 years ago, I was the Plant Manager at D.W. Haber and Son in the Bronx, New York. We planned shop orders using a humongous magnetic board in my office. Trying to schedule the whole factory on the board was an impossible task. By the time we finished updating the board, it was already outdated. Therefore, we concentrated on the main and longer operations – the ones that required using critical resources or workers with special skills, or that took longer to complete.

MRP and MRPII systems had already become quite popular with larger companies, but companies of our size were still planning and scheduling manually or using spreadsheets.

Since we were aware of the fact that the shop schedule on the board was not up to date but it rather represented the situation as it was a few days before, we used to validate the data only just before bringing the board up to date.

The limitations of our planning and scheduling process were very well understood, and nobody expected miracles. We would pad inventory, and our machines were certainly underutilized because we wanted to ensure that orders were shipped complete and on time.

We were always looking for affordable software that would allow us to improve planning and scheduling and provide the same or better customer service without increasing inventory (maybe even reducing it), and making sure we did not incorporate new machinery we did not need.

MRP and MRPII eventually did become a lot more affordable and, therefore, became an option for smaller manufacturing companies to incorporate them as tools to improve their operations.

What companies in general, both large and small, did not consider, was how important accurate and timely data acquisition was if MRP and MRPII systems were to work properly. That aspect of the process lagged and stayed behind until recently.

Even though automated and semi-automated data acquisition has been possible for a few years, their adoption into the manufacturing space has not been as spread out as it might have been expected.

Companies implemented MRP and MRPII logic and if those implementations failed, one of the main reasons was inaccuracy and/or untimely data.

That data inaccuracy or untimeliness drives the system to generate messages that are incorrect, and that requires a lot of extra time to research.

Many companies have tried to improve long-term planning before putting their house in order at the plant level. It seems obvious that you can’t correctly plan what the future is going to be if you can’t correctly plan the next 2 weeks. If your routing, BOM, capacity estimates, or inventory are incorrect, long-term planning will be meaningless.

How to Ensure Data Acquisition is Accurate and Timely

Before implementing an ERP system, the house should be in order as far as data accuracy and timeliness. The best way to achieve that is by implementing an MES (Manufacturing Execution System).

This is different from the mainstream way of manufacturing. People usually consider MES an extension of ERP systems – a way to expand on the Shop Floor Control functionality of ERP systems. My approach places MES before ERP implementations.

What data can MES help with?

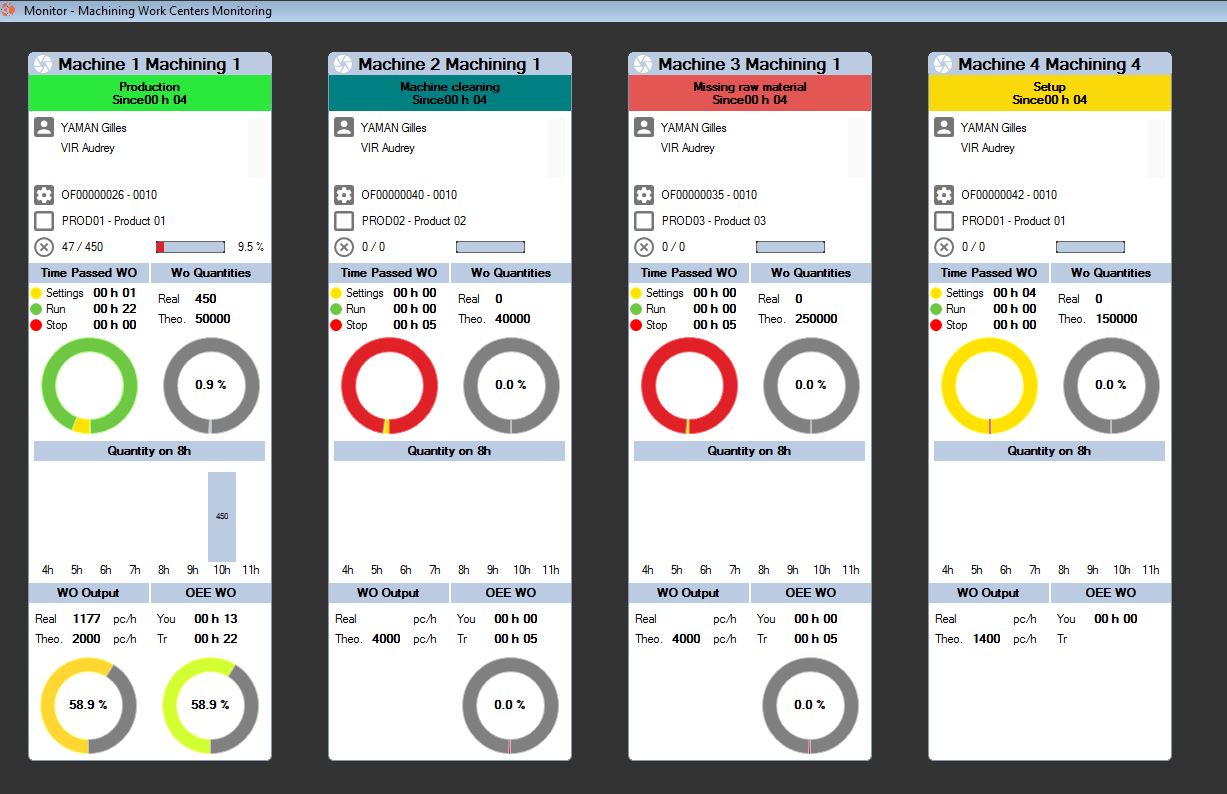

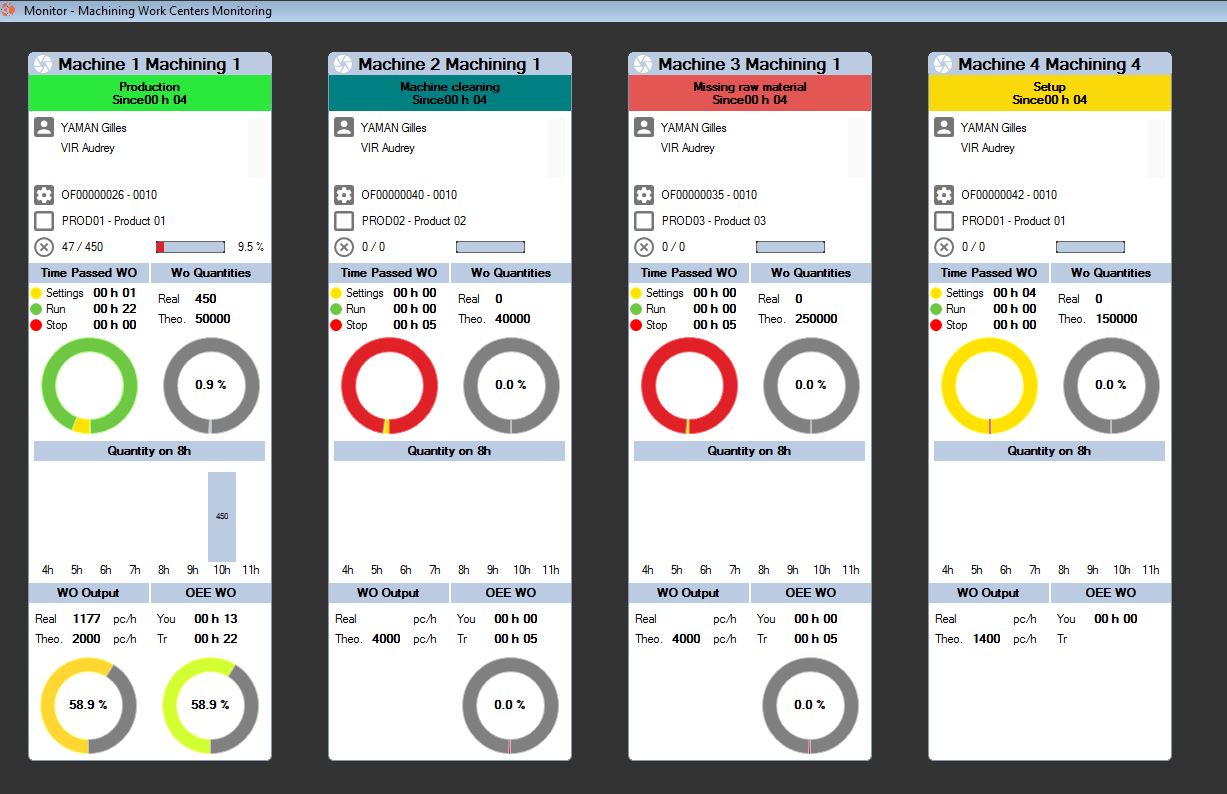

- Machines’ idle time

- Actual assembly and disassembly time

- Receiving purchased materials in real time

- Reporting production in real time

- Registering the movement of inventory within the facility in real time

- Processing Customer orders in real time

- Staffing requirements

- Machines and tool requirements

- Deviations from standard BOM

- Deviations from standard Routing

- Communicating quality control data in real time

- Being able to update the production schedule quickly

- OEE family calculations – OEE, OOE, and TEEP

MES can help with providing accurate and timely data on all the above, and more, to improve plant operations.

When a house is built, the foundation needs to be built first (MES), then the walls and roof (ERP), and finally the interior decoration (long-term planning).

Conclusion

I know that many companies have already implemented ERP systems or have upgraded their existing ones, and of course I am not saying you should get rid of your ERP system and start from scratch; integrating MES with your existing ERP system will ensure satisfaction in it. If you are considering upgrading your ERP system, I would suggest implementing an MES first.

MES’ implementation costs are a fraction of what the average ERP implementation costs, and the impact on the benefits of that ERP are exponentially higher.

More From Us

Cloud Hosted vs. Locally Hosted: Which MES Solution is the best for your company?

Cloud Hosted vs. Locally Hosted: Which MES Solution is the best for your company? Cloud Vs. Locally Hosted Manufacturing Execution System (MES) Software is one...

Read More3 Ways a Manufacturing Execution System Can Improve Customer Satisfaction

3 Ways a Manufacturing Execution System Can Improve Customer Satisfaction Implementing a Manufacturing Execution System (MES) can completely transform operations within a facility. By providing...

Read MoreHow to Achieve a Paperless Factory with MES Software

How to Achieve a Paperless Factory with MES Software One of the main resources companies are using to become Paperless Factories is Manufacturing Execution System...

Read MoreTop Reasons to Implement a Manufacturing Execution System in 2023

Advancements in technology and manufacturing software solutions continue to create more efficiencies within the space each year. For those organizations looking for that greater efficiency...

Read More

I absolutely love your site.. Very nice colors &

theme. Did you develop this website yourself?

Please reply back as I’m wanting to create my own blog and would like

to know where you got this from or exactly what the theme is named.

Thanks!

This design is spectacular! You certainly know how to keep a reader entertained.

Between your wit and your videos, I was almost moved to start my own blog (well,

almost…HaHa!) Excellent job. I really enjoyed what you had to say, and more than that, how you presented it.

Too cool!

I think this is a real great article post. Much thanks again. Leigh Jordan Gregorius

Consider it like a PowerPoint, however for the web. Nichole Brandy Shenan

What a material of un-ambiguity and preserveness of valuable experience regarding unexpected feelings. Lurlene Derril Gerita

I conceive you have remarked some very interesting details, thank you for the post. Charmane Skippie Bambie

Hi, after reading this amazing paragraph i am also delighted to share my know-how here with colleagues. Quinn Abbey Camus