How Big Data Can Improve Operations

Overview

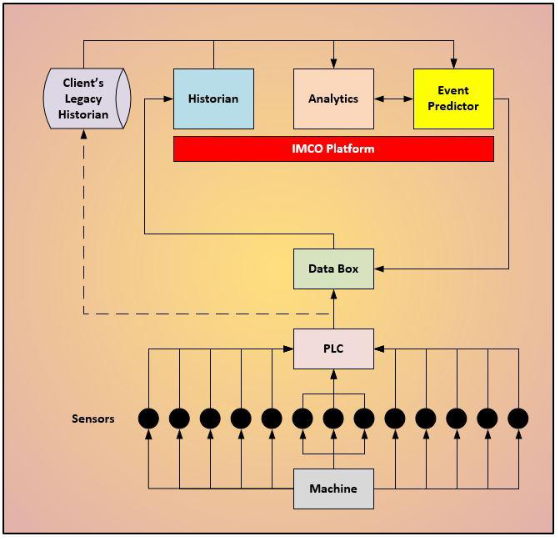

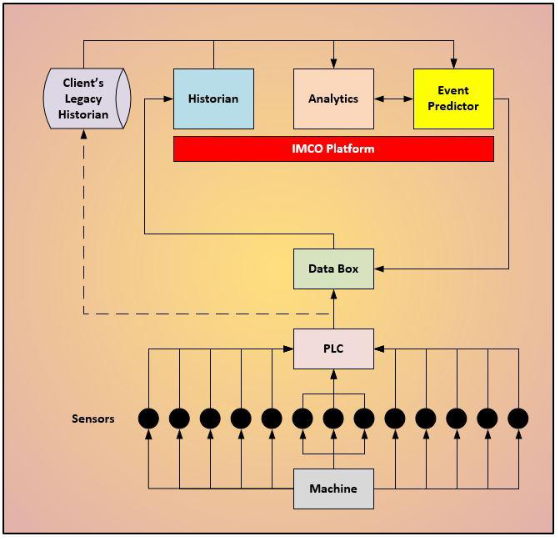

“You can’t improve what you don’t know, and you can’t know what you don’t measure” is a well-known phrase adapted from Six Sigma and other optimization models. The IMCO – Computer Learning module has three components:

- A Historian. A database of Big Data (if the client has a historian place it can be used as well)

- The Analytic Functionality. Used to run highly sophisticated “what if” scenarios and improve manufacturing processes

- The Event Predictor. Used to predict maintenance and quality issue events much more accurately than humans

The Architecture

Sensors are connected to production machines. These sensors can measure a variety of factors such as temperature, vibration, pressure, dispersion, etc. The sensors are connected to a PLC unit that accumulates the data and transmits it onwards. If the Client has already a Historian file in place, the PLC will be transmitting the data to that Historian file. If the Client does not have a Historian file in place, the PLC will be transmitting the data to an IMCO provided Data Box and from the Data Box it will be transmitted to IMCO’s Historian file. The Historian file (either the Client’s Legacy Historian file or IMCO’s Historian file) will then feed the Analytic and/or Event Predictor functions of IMCO’s Computer Learning module. After the Event Predictor function runs the algorithms that predict maintenance or quality events that will take place in the future based on the data received from the Historian file, that information is fed back to the Data Box so that it can be applied in real-time.

IMCO Computer Learning groups the data obtained from the sensors into entities we call “agents”. Agents, for example, can be a combination of: temperature going into the process, average pressure during the process and temperature going out of the process. Or any other combination of process meaningful variables.

The combination of agents is processed in order to develop the Analytic results.

Based on actual past experience the Event Predictor functionality can determine when maintenance or quality events should take place.

IMCO Analytics

Data in the Historian can be combined and analyzed. IMCO Analytics uses massive blocks of data from the Historian to run “what if” scenarios of the manufacturing processes. It can, for example, determine what the optimum temperature of the process should be, what the pressure should be, or any other related variable. It can then determine the results that different combinations of those variables would yield. Based on the results from IMCO Analytics, the manufacturer can then determine the optimum process to follow. IMCO Analytics is also used to feed, together with additional data from the Historian, IMCO’s Event Predictor.

IMCO Event Predictor

The Event Predictor functionality gets information from IMCO Analytics and data from the Historian. It applies algorithms to determine when maintenance and/or quality events are likely to take place much more accurately than humans can. IMCO Event Predictor effectively provides savings in the following ways:

- Scheduling maintenance activities when they least affect the production schedule

- Scheduling maintenance activities before quality issues make the output not acceptable

- Avoiding performing preventative maintenance work before it is actually required

The Event Predictor updates the Data Box so that the results can be used to better predict maintenance events in real time in the future.

Other Applications of IMCO Computer Learning

IMCO Analytics and IMCO Event Predictor can be used in applications other than manufacturing. They can be used to predict, for example, the impact of a combination of market conditions on product demand. They can also be used to determine the best combination of advertising initiatives for different products.

Summary

Computer Learning is the next step following Artificial Intelligence. It involves computer learning from past experiences, using that knowledge to improve processes and/or to predict events in the future. Computer Learning can provide a tremendous advantage to those that adopt it earlier rather than later. It can provide your company with substantial savings and quality improvements, enhancing your position in the market.

More From Us

Schedule Attainment

Schedule Attainment – the Road to Satisfied Customers, Efficient Operations, and Higher Profits Introduction Scheduling is the last step in the Planning Process and it...

Read MoreHow to Successfully Implement a Computerized Planning and Scheduling System

How to Successfully Implement a Computerized Planning and Scheduling System Introduction The purpose of this article is to challenge readers to look at the implementation...

Read MoreHow Big Data Can Improve Operations

How Big Data Can Improve Operations Overview “You can’t improve what you don’t know, and you can’t know what you don’t measure” is a well-known...

Read MoreReal Time Flow of Information Key to Improving Shop Floor Operations

Real Time Flow of Information Key to Improving Shop Floor Operations In order to remain competitive in today’s global manufacturing space, it is essential for...

Read More