Manufacturing Execution System

Full Digital Shop Floor Control

Become more productive, increase efficiency, and lower costs

CIMAG-MES was designed for small to mid-sized manufacturers to have access to customized manufacturing solutions. Reduce scrap and rework, up and down traceability, increase uptime, and overall lower costs help keep your operation competitive.

Explore the features and benefits

- REDUCE SCRAP & REWORK

- ENHANCE TRACEABILITY

- INCREASE UPTIME

- LOWER COSTS

Reduce scrap and rework

- Real Time Communication of QC Issues

- Automatic Adjustment to QC Fields

- Avoiding Errors Through Preventative Maintenance

Enhance traceability

- Tracing down to Materials, Personnel, and Tools

- Provides Up and Down Traceability

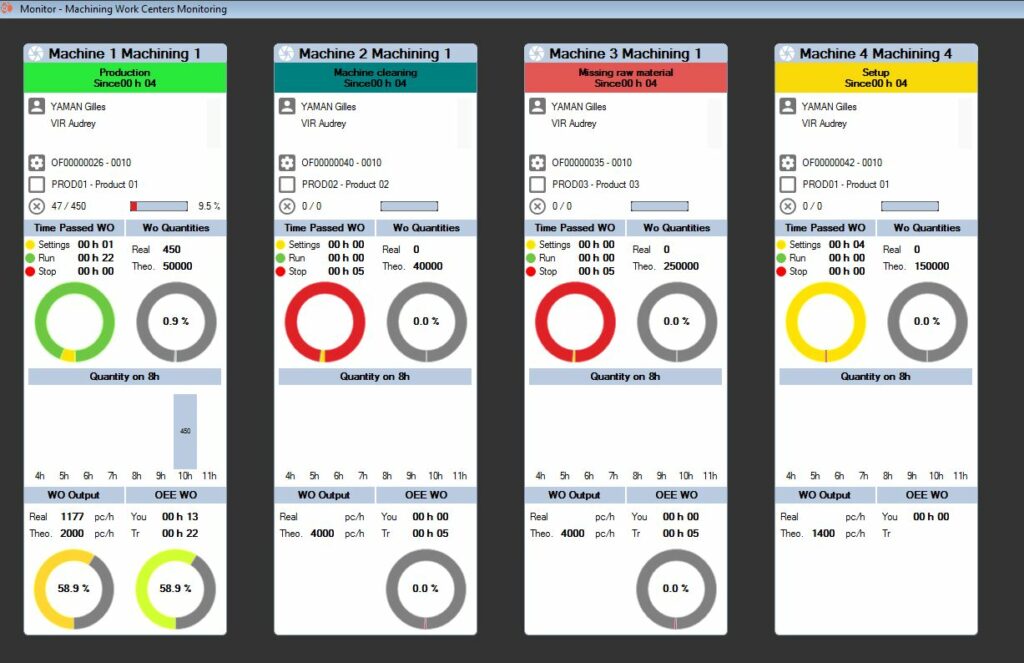

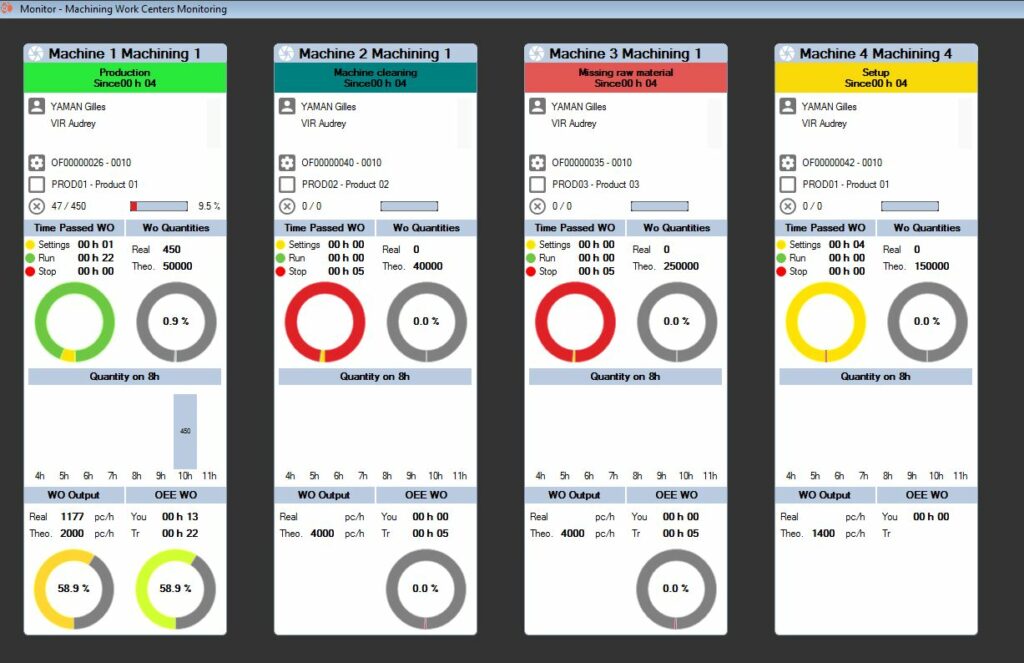

Increase uptime with Scheduling tools and real-time visibility

- Minimize Idle Time

- Reduce Setup and Disassembly Time

- Improve Materials and Components Staging

- Alerts of Conflicts: People, Machines, and Tools

- Alerts to Machines not Producing

- Alerts to Stopped Machines

- Real Time Maintenance Communication

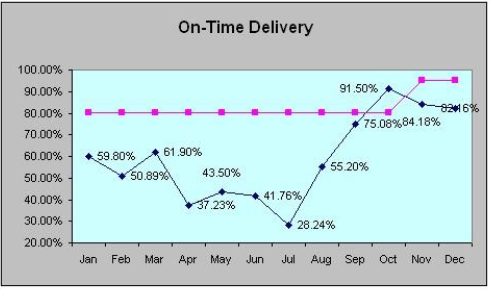

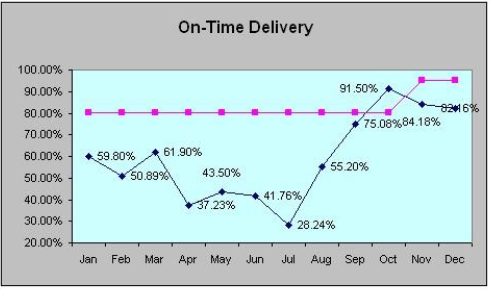

Lower operating costs with improved operations liability and customer service

- Realistic, Up-to-date Production schedule

- Reducing Response Time to Issues

- Reducing Working Capital Tied Up in Inventory

- Real Time Visibility across the entire company

- Improving OTIF (On Time in Full Delivery)

- Providing Customers with Reliable Delivery Dates

BROCHURES

CIMAG-MES: Digital Manufacturing Execution System

State of the art Shop Floor Control System meeting all 14 ISO requirements.

Manufacturing Execution System for Small to Mid-Sized Companies

Reduce Scrap and Rework

Improve Up & Down Traceability

Minimize Idle & Downtime

Reduce Setup & Disassembly Time

Reduce Response Time

Reduce Working Capital Tied Up in Inventory

Have a challenge? We have the solution

Maximize uptime with absolute minimum materials.

Real-time upstream and downstream product and process traceability

Respond successfully to changing demand

Support any discrete manufacturing process on-the-fly

Use computer learning to avoid unplanned downtime and increase productivity.

Quality Management for all aspects of the operation.

Latest insights for exceptional quality

Inbound material quality, in-process quality, outbound product quality, and corrective & preventive actions

Improving Manufacturing Lead Time in 2023

Technological innovation is driving a fourth industrial revolution (Industry 4.0) within the...

Read MoreWhat to Expect in the Chemical & Plastics Industries in 2023

Like many industries, the chemicals and plastics manufacturing space has drastically transformed...

Read MoreForward vs. Backward Traceability in Manufacturing

Traceability remains a buzzword in the manufacturing world, and for good reason....

Read MoreLearn how IMCO Software can help you achieve perfect execution process

Request a consultation to see how we can help