Keeping Your Data Safe: Blockchain Manufacturing

Changing to a different network style is a big decision, but it’s a very important one to make. As innovations take over the manufacturing space, decision-makers should consider the advantages of blockchain manufacturing. Shifting to blockchain-based manufacturing can be more secure, more user-friendly, and (most importantly) can save you money! Keep reading to discover the power of blockchain manufacturing and how it can keep your data safe. The same technology that helps Bitcoin keep their money secure could become the most widely used type of network in manufacturing.

Blockchain Manufacturing & Traceability

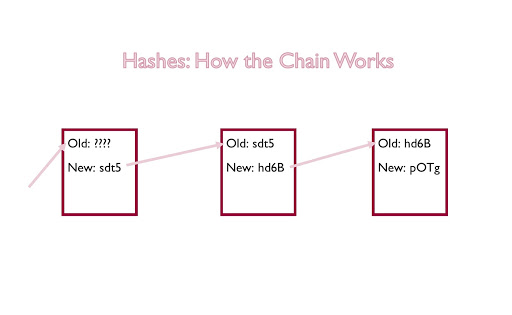

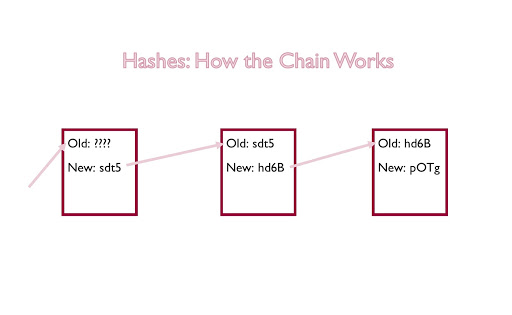

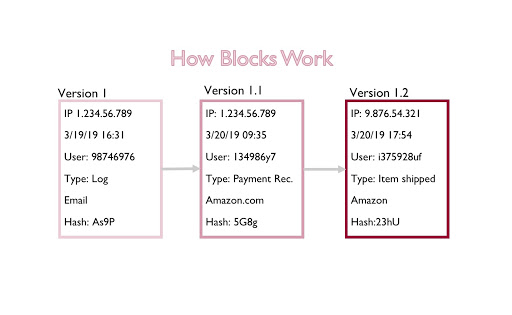

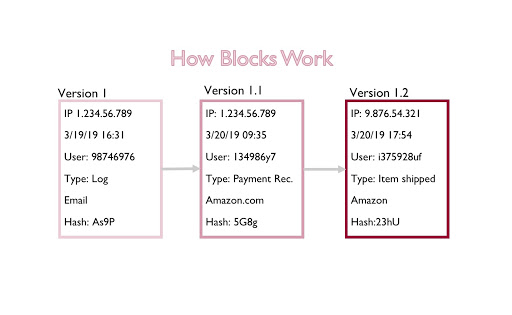

Blockchain manufacturing is the process of putting data into blocks. These blocks contain the data, a hash (encryption), and other identifying markers. Each time an update is made, the information is encrypted, and the hash makes it impossible to tamper with previous blocks. A new block must be made in order for the data to be updated. Every time a change happens, a new block forms, with a new hash/encryption.

According to Forbes, combining blockchain and IoT will revolutionize product safety, track-and-traceability, warranty management, Maintenance, Repair & Overhaul (MRO), and lead to new usage-based business models for smart, connected products. The way these blocks are stored chronologically in a chain allows Manufacturing Execution System (MES) Software like CIMAG to quickly provide the valuable information listed above in real time for companies. Utilizing MES Systems in combination with blockchain manufacturing is great for enhancing traceability.

Benefits of Blockchain Manufacturing

Blockchain manufacturing uses a Peer-to-Peer(P2P) network system instead of having a central server storing all of the data. A P2P network has a couple of benefits:

- Security

- Set-up ease

- Effective collaboration

- Scalability

- Fast services when there is an issue

The blockchain system has a couple of extra benefits on top of using a P2P server:

- Even more security when coupled with the P2P network

- Cost saving

- Easy traceability

- Increased focus on customer

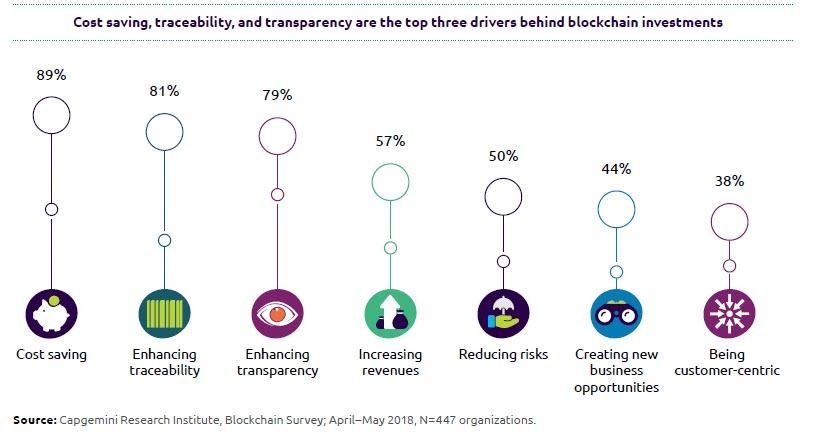

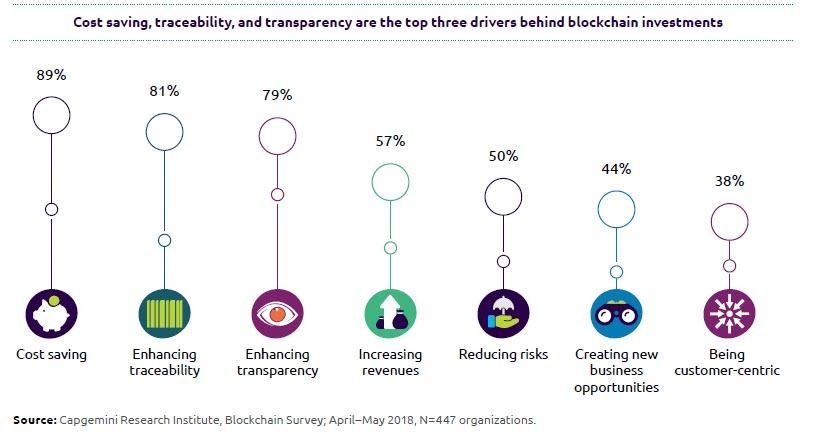

Research supports the fact that blockchain systems are keeping up with the currently growing system of moving from a paper trail of information within a factory to a completely electronic approach. Automation is the future of manufacturing with MES and blockchain systems. From improving ROI, enhancing traceability, and increase visibility…these two powerful systems are game changers for manufacturing companies. In fact, according to the Capgemini Research Institute, below are what companies think are the most beneficial parts of blockchain investments:

Why are blockchain and P2P networks more secure than a central server?

The first thing that makes this method more secure than others is that it uses hash encryption. A hash is an encryption device that takes the inputted data and outputs a hash of a specific length.

Hashes go along with the blocks, because every time a new block is created, a new hash is generated with it, using the old hash as the input:

The P2P network is the other part of the system that produces security. Because of this network, you would think it would be easy for a computer with malicious intent to join the server and corrupt the information by updating a previous block. This is not the case, however, because there is a 2-step verification process involved in creating new blocks/updating old blocks:

- The business develops a set of rules that each update has to pass before going on to step 2

- All peers must agree on the new block in order for it to be created.

The P2P network keeps itself safe because of the members, no matter the number.

All of this makes the blockchain tamper-resistant. Of course, people are smart, and they will find ways to get in. The blockchain system has a defense against this as well. Every block is stamped with five items as soon as it is made:

- Where it was created (computer IP address)

- Who created it

- When it was created (a time-stamp)

- What kind of data was tampered with

- How the data was exchanged (if it was a transaction with a customer)

Still not convinced?

Utilizing this method does more than just keep your company’s data safe; it can save you money as well! (Especially when in combination with an MES or ERP system!) When you have this level of security, it reduces your post-manufacturing fault detection costs by catching issues before they leave the site. This can also reduce your liability costs by reducing the number of customers injured by the product. Lastly, it can reduce/eliminate the need for product recall since the chain can and will catch most defects before they leave the factory since blockchains are in near-real time. To learn more about blockchain manufacturing and other manufacturing solutions provided by IMCO contact us today.

Your company can be inspired by blockchain manufacturing as well!

For more information, check out these links:

https://www.capgemini.com/wp-content/uploads/2018/10/Digital-Blockchain-in-Supply-Chain-Report.pdf

https://www.syncron.com/news/blockchain-can-transform-manufacturing-industry/

https://www.disruptordaily.com/blockchain-use-cases-manufacturing

More From Us

MES: Why you need one if you manufacture anything

IMCO Software has created an elegant solution that improves efficiency and profitability in manufacturing by giving manufacturing decision-makers real-time information about the current conditions on...

Read MoreThe Importance of Supply Chain Agility

The Importance of Supply Chain Agility Most people have a general understanding of what a supply chain is. Essentially, everything that goes into producing and...

Read MoreEnergy Management Systems – Balance Production & Energy Consumption

Energy Management Systems – Balance Production & Energy Consumption At the start of all manufacturing processes, there is energy. In fact, all products you see...

Read MoreTop Reasons to Implement a Manufacturing Execution System in 2023

Advancements in technology and manufacturing software solutions continue to create more efficiencies within the space each year. For those organizations looking for that greater efficiency...

Read More